Communiqué de presse -

Minebea Intec presents leading technology for industrial weighing and inspection at ProPak Africa 2025

Minebea Intec, a global leading manufacturer of industrial weighing and inspection technologies, will be exhibiting at ProPak Africa 2025 in collaboration with respected South African partner Precision Control Pty Ltd. ProPak is one of Africa's leading exhibitions and conferences for the packaging, processing, printing, and plastics industries. From 11 to 14 March, visitors to the Johannesburg Expo Centre can explore Minebea Intec's comprehensive product portfolio, featuring solutions for checkweighing, foreign body detection, static and process weighing, as well as truck weighing. A highlight of the stand will be live demonstration units showcasing the functionality and performance of Minebea Intec’s high-precision technologies. Minebea Intec looks forward to welcoming visitors to Stand D11 in Hall 6.

The packaging industry in Africa is on the rise, driven by population growth, the expansion of the retail sector and the demand for sustainable packaging solutions. At the same time, companies are faced with challenges such as meeting international quality standards, optimizing production processes and implementing food safety technologies. Minebea Intec offers a comprehensive portfolio of weighing and inspection technologies that meet the requirements of both local manufacturers and international corporations.

Minebea Intec will be presenting a selection of its most advanced technologies at Propak Africa, developed specifically for the packaging industry.

High-Precision Metal Detection with Mitus® and Vistus®

For the detection and rejection of metal contaminated products, Minebea Intec offers high-precision metal detectors. Manufacturers who opt for metal detection benefit in many ways. First and foremost is the assurance of product quality and consumer protection. Contaminated products can lead to expensive recalls and brand damage. Additionally, the efficient operation of metal detection systems ensures minimal downtime and smooth production processes, enhancing overall productivity and cost-effectiveness. Minebea Intec offers two metal detection systems for the industry, Vistus®and Mitus®. The premium solution Mitus® has an even higher detection sensitivity than Vistus®. But whether you choose the Mitus® or Vistus® metal detector: Both solutions can be integrated one-to-one with our conveyor, free-fall or pipeline systems.

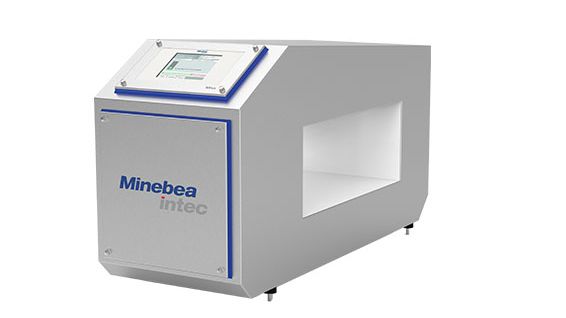

Compact Precision Meets Innovation: Discover CoSynus®

Checkweighers are used in the packaging industry to ensure that products meet the specified weight and thus comply with legal and operational standards. The CoSynus®checkweigher combines the functions of a checkweigher and a metal detector in a single compact device. This innovative solution ensures precise weight control and simultaneous metal detection, thus increasing the efficiency of production lines. It is particularly suitable for manufacturers who have limited space but do not want to compromise on quality.

A special highlight of the CoSynus®is the new Blue HMI (Human Machine Interface), an innovative development for checkweighers. Designed for intuitive touchscreen operation, it offers unparalleled ease of use, enhancing convenience and efficiency. With clearly structured menus, users can adjust weight checks, analyze production data, and generate reports in just a few steps—directly on the device. This innovation ensures seamless integration into production lines, minimizes set-up times, and boosts efficiency in the packaging industry. Trade fair visitors can explore its advantages through a video presentation, showcasing how this solution is shaping the future of checkweighers.

Advanced X-Ray Inspection with Dylight and Dymond S

X-ray inspection systems not only detect products contaminated with metal, but also with glass, rubber, stones, plastic parts or bone fragments. They can also perform in-line quality checks such as weight determination, component counting, detection of missing or defective products, fill level checks and closure integrity checks. Minebea Intec offers a wide range of X-ray systems for the inspection of packaged products. Typical applications include cartons, boxes, bags, trays and portion packs containing a variety of dry or liquid food products.

The compact and powerful X-ray inspection system Dylight, which will be shown at the fair, offers an efficient solution for detecting foreign bodies in packaging. Its compact design makes it ideal for smaller production environments, while maintaining the high quality and reliability of Minebea Intec products.

The Dymond S X-ray inspection system provides maximum safety through multi-sided radioscopy, ensuring reliable foreign object detection in high, upright-standing packaging. With its hygienic design, high-speed image processing, and seamless integration into automated production lines, it guarantees efficient and precise quality control in industrial applications.

Meet us at Propak Africa in Johannesburg

The Minebea Intec team warmly invites you to visit them at stand D11 in Hall 6, where they will be presenting tailor-made solutions for the specific requirements of your production processes. In addition to Checkweighers, Metal Detectors, and X-ray Inspection Systems, the extensive weighing portfolio also includes high-precision scales for static weighing and Load Cells for vessels, silo, or truck weighing. Whether you need solutions for counting, fill level control, batching, or dosing – alongside foreign body detection and weighing – Minebea Intec’s fully automated systems ensure efficiency and safety. The company provides full support throughout the entire project planning process.

"Propak Africa is a key platform for us to connect with local manufacturers and demonstrate how our advanced weighing and inspection technologies can enhance both safety and productivity”, says Willy-Sebastian Metzger, Director Business Development & MarCom of Minebea Intec. “We are committed to providing the optimal equipment for precise weighing and inspection that is complemented by an outstanding local sales, support and service team from our trusted partner Precision Control. Together, we ensure our customers receive not just superior products but also the expertise and service they need to optimize their production processes."

6,228 characters (with spaces)

Liens connexes

Thèmes

Tags

Minebea Intec est un leader mondial dans la fabrication de technologies de pesage et d'inspection industrielles. Basée à Hambourg, l'entreprise propose des produits et des services qui sont synonymes d'innovation, de performance et de fiabilité depuis plus de 150 ans. Son portefeuille de produits comprend notamment des balances à plate-forme haute résolution, des cellules de pesage, des balances pour conteneurs et silos, des trieuses pondérales, des détecteurs de métaux, des systèmes d'inspection radiographique et visuelle ainsi que des solutions logicielles intuitives. Plus de 1.000 collaborateurs répartis sur 18 sites augmentent la précision et l'efficacité des processus de pesage et de production des clients industriels. Un réseau de plus de 200 partenaires dans 71 pays complète les sites de vente et de service de cet acteur mondial. La force de performance et la qualité allemande prononcée se reflètent dans la promesse de la marque "the true measure".

Minebea Intec fait partie du groupe MinebeaMitsumi, un fournisseur leader de pièces de fabrication de haute précision comme les roulements à billes ou les moteurs, ainsi que de composants électroniques de haute qualité comme les capteurs, les antennes et les solutions IoT. Le groupe, dont le siège est à Tokyo et qui emploie environ 84 000 personnes dans le monde, a déclaré un chiffre d'affaires net consolidé de 1 402 127 millions de yens (environ 8,9 milliards d'euros) pour l'exercice 2024.